The zip plug, also known as a slide on vampire plug or Gilbert plug, is the key to beautiful and bespoke holiday lighting displays. Not only are they the answer to having the perfect length of lights for your roofline, they’re also helpful for hobbyists who are creating marquee lights, miniature Christmas villages, or other completely custom designs.

Whether you’re a professional installer or just a hobbyist doing some DIY lighting, the vampire plug opens up a whole new world of light installations! Though cutting and altering electrical wire may sound complicated, it’s extremely simple - let us explain!

What is a Zip Plug?

A zip plug is a small electrical component that allows you to cut your Christmas light wire and extension cord for seasonal use. There are both male and female plugs available, with many female plugs giving you the option to turn them into an in-line plug. This means you can branch out from your main line anywhere along the wire without having to cut it!

A zip plug is often called a “vampire plug” because of the metal teeth that bite into the wire. Zip plugs and the wire used with them are polarized, meaning there is a specific tooth that will pierce into each side of the wire. This means you have to be certain you’re installing the plug correctly, with the correct tooth lined up with the correct side of the wire. The tooth that is attached to the larger prong on the plug (or the larger hole on a female plug) corresponds with the neutral side of the wire. So how do you know which side of the wire to line it up with? We’ll get to that a little later after we discuss what type of wire to pair zip plugs with.

Pairing Vampire Plugs with Electrical Wire

To properly introduce the use of zip plugs, we must also talk about the wire they’re compatible with - SPT electrical wire. SPT stands for Stranded, Parallel, Thermoplastic. To break this into layman's terms:

- Stranded = thin and bundled wires, ideal for applications where the wire needs to be bent or twisted.

- Parallel = the circuit runs in parallel, meaning that if one bulb goes out on your wire, all of the other bulbs will continue to work. This is in contrast to wire that runs in series (often twisted wire), which is when you will run into the situation where one bulb outage causes the whole wire to go out.

- Thermoplastic = is in reference to the PVC insulation around the wire, which is both flexible and heat resistant.

When pairing zip plugs with SPT wire, you need to ensure that you’re buying plugs and wire that are compatible with one another. You’ll find two types of SPT wire in the holiday lighting industry, SPT-1 and SPT-2. So what’s the difference?

SPT-1 vs SPT-2 Wire

The difference between SPT-1 and SPT-2 wire is pretty simple. The different numbers are in reference to the thickness of the thermoplastic insulation around the wire.

- SPT-1 wire has a 0.03 inch insulation thickness

- SPT-2 wire has a 0.045 inch insulation thickness - in other words it’s 50% thicker than SPT-1

So what does this actually affect? A popular misconception is that SPT-2 wire can handle more amperage than SPT-1 wire, but this is false. The additional insulation is great for places that experience cold winters, and it also provides greater UV protection in the summer time. As a Canadian-born business, Big Star Lights sells exclusively SPT-2 wire due to its ability to stand the test of time in harsh cold winters and hot summers.

Pairing Plugs with the Right Wire

Because the insulation of the wire is thicker in SPT-2, this means you have to be certain you’re matching the right size of zip plug with your wire. SPT-2 wire will be too big for SPT-1 plugs, not only in width, but the teeth of the plugs are often too short to pierce into the wire deep enough to make contact with the copper inside. And SPT-2 plugs can be difficult to line up properly with SPT-1 wire, since the plug fitting will be larger than the wire itself. So the rule of thumb is as simple as this: SPT-1 wire should be paired with SPT-1 plugs, and SPT-2 wire should be paired with SPT-2 plugs.

Installing the Plug

As previously mentioned, one side of the plug has a larger prong than the other. This larger prong should be lined up with the neutral side of the wire. There are a few tricks to ensure you’re lining up the wire correctly with the plug to ensure a complete electrical circuit.

SPT wire should have a “ribbed” side of the wire. You’ll notice when you rub your finger over the sides of the wire that one has very narrow ribbing, and one side is totally smooth. This ribbed side is the neutral side!

- One industry mnemonic phrase for remembering this is “Ribbed Side Right”, or - less politely - "The Fat Guy Always Eats the Ribs", as the larger prong is most often associated with the tooth on the ride side of the plug.

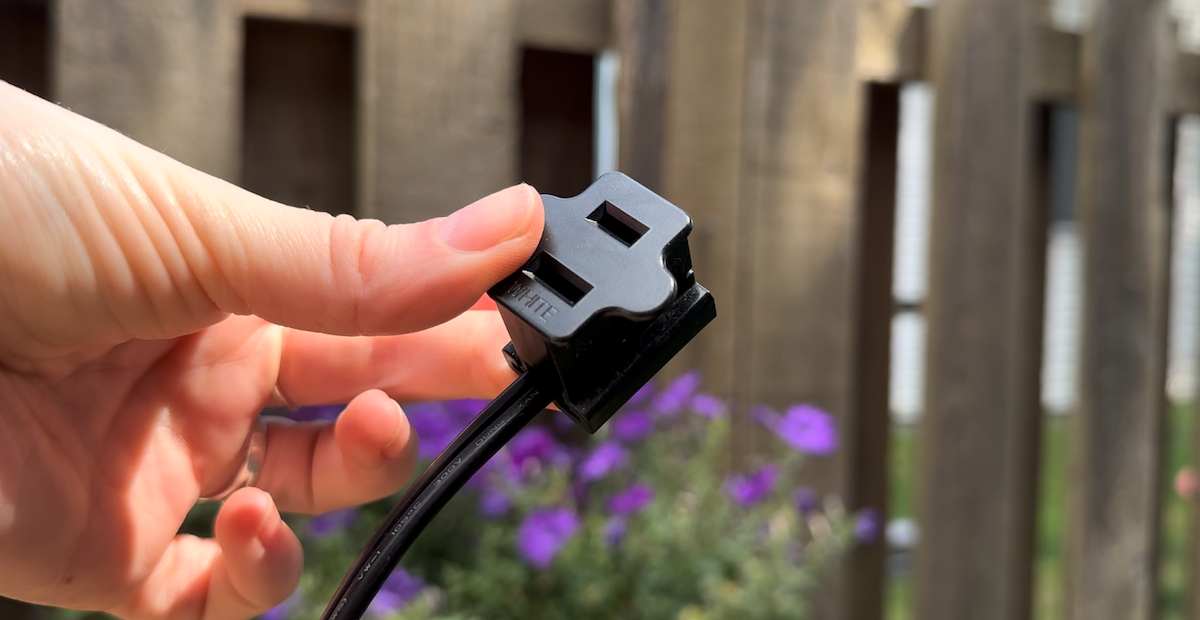

- Many plugs nowadays will have “RIBBED” written conveniently on the side of the plug that the ribbed wire should be lined up with.

Step by Step Installation Guide

Quick safety reminder: never cut a cord that is plugged in!

1. Using wire cutters, split the end of your wire by about 1/4 of an inch and rub the PVC coating to cover the copper. This helps to prevent any potential electrical issues.

2. Locate the ribbed side of the wire by rubbing the wire and feeling for the texture. Line the ribbed side up with the right side of the plug, or the tooth coming from the larger of the two prongs on a male plug (or the larger hole on a female plug). You can also check the plug to see if “RIBBED” is written on one side (see photo).

3. Place the wire into the channel at the back of the plug. Insert it as deep into the channel as you can.

5. Press down on the wire so that the teeth bite into the insulation

6. Slide the back onto the plug. If you’re having trouble closing it all the way, the handles of your wire cutters can help here!

7. Your plug is now installed! Wasn't than an easy installation?

To have a complete circuit, you’ll need to have one male plug and one female plug at either end of the wire. You can have multiple female in-line plugs installed along the line, but you can never have more than one male plug on a circuit.

For installing female in-line plugs, check to see if your female plug has a removable tab at the back. If it does, this means it’s in-line compatible! You can easily remove this tab with your wire cutters and place the plug onto your line wherever you need it.

And that's as simple as it gets! While zip plugs have long been used in the Christmas lights industry, they've only recently broken into the residential market. Take advantage of their availability to build your custom light display today! Have any questions before starting your project? Feel free to contact us and we'll be happy to help you out.

2 comments

I have a Christmas wreath with 3 male connectors 2 female connector how do I line them up

Just a quick question.

I have an outside C9 bulb Christmas light installation (SPT-2 wire and Plugs both male and female) that I am trying to tweak a bit and was looking at the current set up and noticed that through out (everything works fine) that the Ribbed part of the wire is on the small prong (hot side).

If the entire installation was wired this way, does it matter that the ribbed side of the wire was not wired to the big prong (neutral side) of the wire setup through-out?? (or is there a size difference or something for why it would have to be ribbed side of the wire to the neutral side)

Thanks for your help with this,

Jason Peters